IBhasi yeBhasi yaseTshayina ekumgangatho oPhezulu

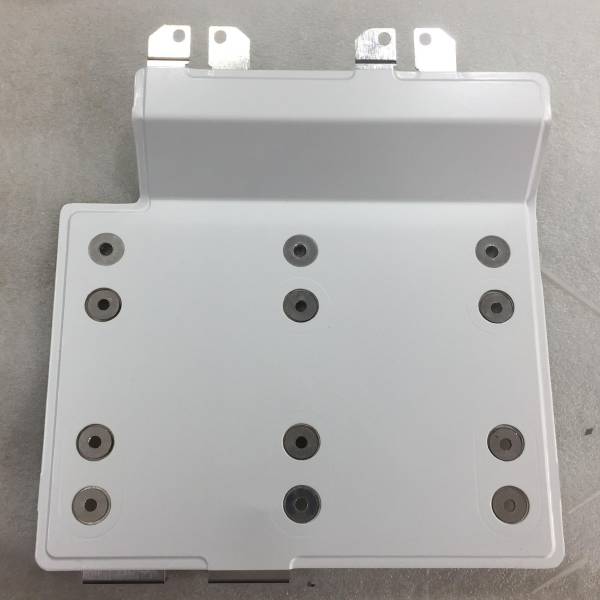

Ibha yebhasi ye-laminated, ebizwa ngokuba yi-composite bus bar, ibha yebhasi ye-laminated no-inductance, ibha yebhasi ye-inductance ephantsi, ibha yebhasi ye-elektroniki, njl. Ibha yebhasi ye-laminated yenziwe ngezinto ezininzi zokuqhuba kunye ne-insulation material.

Ibha yebhasi enelayitiwe nguhola weendlela zokuhambisa amandla ombane. Xa kuthelekiswa nemowudi ye-wiring enzima kunye engcolileyo, ineempawu ezifana ne-impedance ephantsi, i-anti-interference, ukuthembeka okulungileyo, ukugcina indawo kunye nokuhlanganisa ngokukhawuleza. Isetyenziswa ngokubanzi kuthutho lukaloliwe, umoya kunye ne-solar inverters, ii-inverters zamashishini, iinkqubo ezinkulu ze-UPS okanye ezinye izinto ezifuna ukuhanjiswa kwamandla ombane.

Kwizixhobo zethu zokuvelisa, nceda u tyelele amaziko ethu ( https://www.scdfelectric.com/copper-aluminum-bus-bars/ ).

Imivalo yebhasi elaminethiweyo zezo zilungelelanisiweyo ngokusekelwe kwimizobo yabasebenzisi kunye neemfuno zobugcisa. Zonke iinjineli zethu kumaqela obuchwephesha zineminyaka engaphezu kweshumi yamava okuphuhlisa nokuvelisa imivalo yebhasi elayitiweyo, inokunceda abasebenzisi ukuba baphucule ubume bemveliso kwaye baqinisekile ukuba babonelela ngeemveliso ezikumgangatho ophezulu kunye nenkonzo eyanelisayo kuwe.

Iimpawu zeMveliso

I-1) I-coefficient ephantsi ye-inductance, i-compact structure, igcina ngokufanelekileyo indawo yokufakela yangaphakathi, ukwandisa indawo yokutshatyalaliswa kobushushu, kunye nokulawula ngokufanelekileyo ukunyuka kweqondo lokushisa kwenkqubo.

I-2) Ubuncinci be-impedance bunciphisa ilahleko yomgca kwaye buphucula kakhulu umthamo ophezulu okhoyo wokuthwala umgca.

3) Inokunciphisa umonakalo kumacandelo abangelwa ukuguqulwa kombane kunye nokwandisa ubomi benkonzo yamacandelo e-elektroniki.

4) Ukunciphisa ingxolo yenkqubo kunye ne-EMI, ukuphazamiseka kweRF.

I-5) Amandla aphezulu amacandelo esakhiwo soxhumo lwemodyuli kunye nendibano elula kwaye ekhawulezayo.

Izinto eziluncedo kwiBar yeBhasi eneLaminated

1) I-inductance ephantsi

Imivalo yebhasi elayitiweyo ngamaleko amabini nangaphezulu eepleyiti ezenziweyo zobhedu ezipakishwe kunye, iileya zepleyiti zobhedu zigqunywe ngombane ngezinto zokugquma, kwaye iileya eziqhubayo kunye nezaleko zokugquma ziyalanywa zibe yintlanganisela epheleleyo ngenkqubo enxulumene ne-thermal lamination.

Intambo yokudibanisa yenziwe ibe yindawo enqamlezileyo, eyandisa indawo yomgangatho we-conductive layer phantsi kwecandelo elinqamlezayo langoku, kwaye kwangaxeshanye, isithuba phakathi kwee-conductive layers sincitshiswa kakhulu. Ngenxa yomphumo osondeleyo, iileyile ezidibeneyo ezihambayo zihamba ngokuphambene nemisinga, kwaye zivelisa Imimandla yamagnetic irhoxisa enye kwenye, ukwenzela ukuba i-inductance esasazwayo kwisekethe iyancipha kakhulu. Ngelo xesha, ngenxa yeempawu zayo zeprofayili ecaba, indawo yokutshatyalaliswa kobushushu yanda kakhulu, enenzuzo ekunyuseni kwamandla okuphatha ngoku.

2) Isakhiwo

Ulwakhiwo olubambeneyo, ukusetyenziswa ngokufanelekileyo kwendawo kunye nobushushu benkqubo yokulawula kakuhle.

Ukunciphisa inani lamacandelo kunye nokwandisa ukuthembeka kwenkqubo.

Kulula ukuyifaka kunye nokugcina.

Ilula kwaye intle.

Uqhagamshelo lwebha yobhedu eqhelekileyo

Uqhagamshelo lwebha yebhasi enelaminated

3) Imisebenzi

IiParameters zeMveliso

| Izinto | Idatha yobugcisa |

| amandla ombane osebenzayo | 0 ~ 20kV |

| Ikalwe ngoku | 0~3600A |

| Ubume bemveliso | Ukutywinwa okutshisayo, ukucinezela okushushu ngaphandle kokutywinwa komphetho, ukucofa okutshisayo ukugcwaliswa komphetho. |

| Ubungakanani obukhulu bomatshini | 900 ~ 1900MM |

| Ibanga elibuyisela idangatye | UL94 V-0 |

| Izinto zomqhubi | T2Cu, 1060 AL |

| Unyango lomphezulu we-conductor | Ukucwenga kwesilivere, ukucwenga kwenkcenkce kunye ne-nickel plating |

| Imowudi yoqhagamshelo ngesixhobo | Cinezela i-convex, i-riveting yekholamu yobhedu, i-welding yekholamu yobhedu |

| Ukumelana ne-insulation | 20MΩ~ ∞ |

| Ukukhupha inxalenye | Ngaphantsi kwe-10PC |

| Ukunyuka kobushushu | 0~30K |

UKhetho Lwezinto Zokuqhuba

Ixabiso lebhasi yebhasi ye-laminated inqunywe yimpahla yomqhubi. Ngokweemfuno zokwenyani zesicelo, umsebenzisi unokukhetha ukusebenza ngokufanelekileyo ngokufanelekileyo.

| Uhlobo lwezinto | Tensile strength | Ukwandisa | Ukuxhathisa umthamo | Ixabiso |

| Cu-T2 | 196MPa | 30% | 0.01724Ω.mm2/m | phakathi |

| Cu-TU1 | 196MPa | 35% | 0.01750Ω.mm2/m | phezulu |

| Cu-TU2 | 275MPa | 38% | 0.01777Ω.mm2/m | phezulu |

| Al-1060 | - | - | - | phantsi |

Inkqubo yeMveliso yokuHamba iNcoko yeBhasi yeLaminated

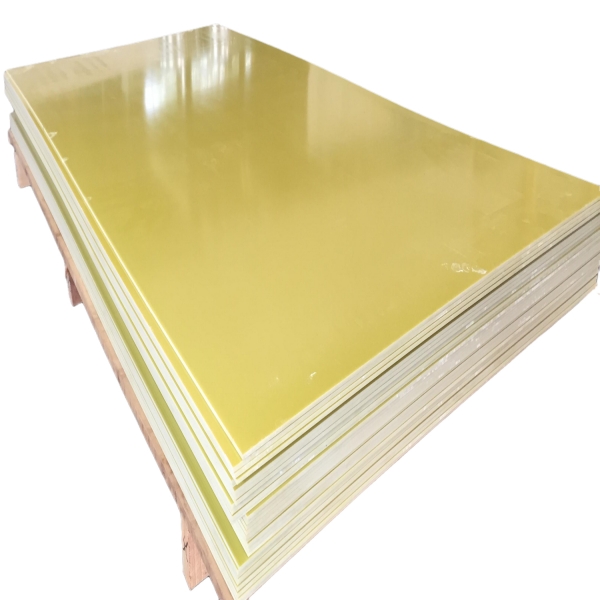

Ukhetho lweMathiriyeli yokuKhusela

I-inductance ye-laminated bus bar iphantsi kakhulu, ekufuneka iqinisekiswe ngezinto ezintle zokugquma. Ukuhlangabezana noluhlu lwe-insulation yombane kunye neemfuno zokusingqongileyo, abasebenzisi banokwenza ukhetho olungcono ngokwesicelo sokwenene.

| Uhlobo lwezinto | Ubuninzi (g/cm3) | I-Coefficient yokwandiswa kwe-thermal | Thermal indlela yokusebenza W/(kg.k) | Inombolo yeDielectric (f=60Hz) | Amandla eDielectric (kV/mm) | Ibanga elibuyisela idangatye | Udidi lokugquma ubushushu(℃) | Ukufunxwa kwamanzi (%)/24h | Ixabiso |

| NOMEX | 0.8~1.1 |

| 0.143 | 1.6 | 17 | 94 V-0 | 220 |

| phezulu |

| PI | 1.39~1.45 | 20 | 0.094 | 3.5 | 9 | 94 V-0 | 180 | 0.24 | phezulu |

| PVF | 1.38 | 53 | 0.126 | 10.4 | 19.7 | 94 V-0 | 105 | 0 | phezulu |

| I-PET | 1.38~1.41 | 60 | 0.128 | 3.3 | 25.6 | 94 V-0 | 105 | 0.1~0.2 | phantsi |

| Uhlobo lwezinto | Iimpawu eziphathekayo |

| NOMEX | Ukuchasana nomlilo okugqwesileyo, ukumelana nobushushu, ukuxhathisa okulungileyo kokutya kweekhemikhali, iipropathi ezilungileyo zoomatshini, ukuxhathisa kwi-radiation kunye ne-flame retardant. |

| PI | Iipropati zombane ezigqwesileyo, iipropati zeekhemikhali ezizinzile, ukufunxa okuphantsi kakhulu komswakama, i-flame retardant |

| PVF | Iimpawu zombane ezilungileyo, ukuxhathisa kweekhemikhali, ukufunxa ukufuma okuphantsi, ixabiso eliphantsi |

| I-PET | Ukumelana nobushushu obugqwesileyo, iipropathi ezilungileyo zombane, ukuxhathisa kwi-radiation, i-flame retardant |

NOMEX

PI

PVF

I-PET

Iimpembelelo zomaleko wokugquma ibhasi ye-DC imi ngolu hlobo lulandelayo:

Ubukhulu bogqume bubalulekile;Ubungqingqwa bomaleko wokugquma ngumsebenzi we-inductance eyongezelelweyo elahlekileyo;

Ubuninzi bomgca we-insulation kuthathwa njengomsebenzi wokukhutshwa kwenxalenye ye-capacitor ephezulu eyongezelelweyo.

I-inductance yebhasi ihambelana ngokuthe ngqo nobukhulu bezinto zokugquma phakathi kweebhasi zebhasi.