Iphepha Elinamanzi leGlasi leMat yeGlasi ...

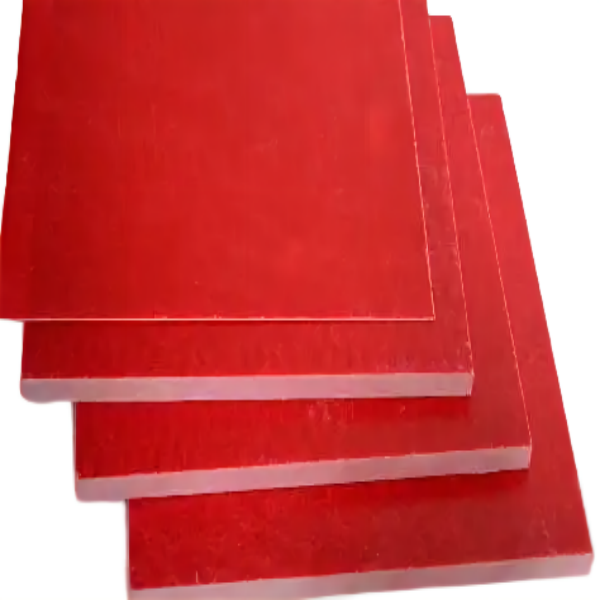

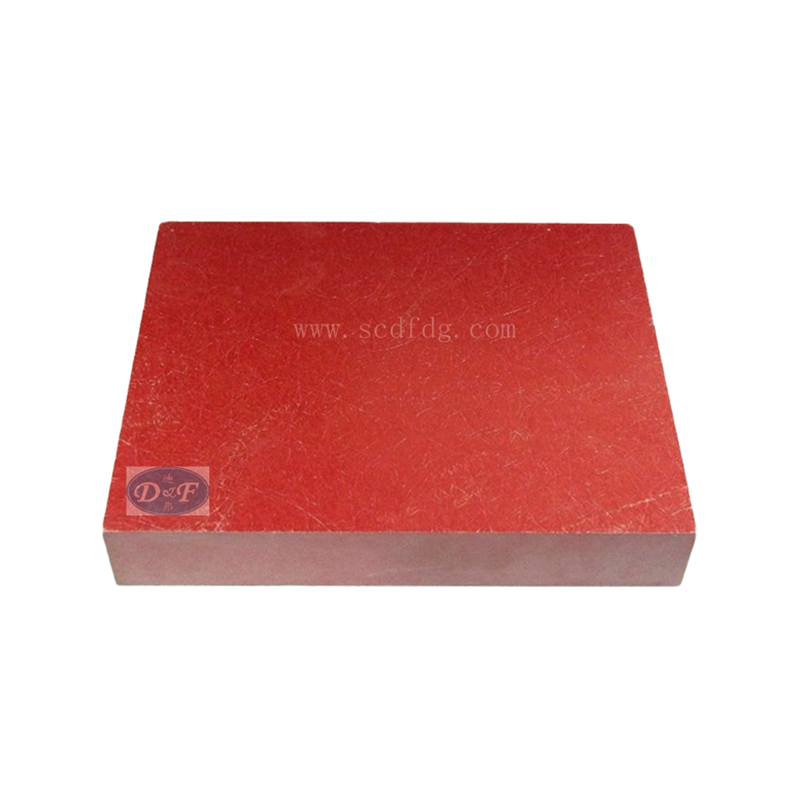

Iphepha Elibunjiweyo le-GPO-3 (elikwabizwa ngokuba yi-GPO3, UPGM203) liqulathe umatrasi weglasi ongena-alkali ofakwe kwaye ubotshelelwe nge-resin ye-polyester engagcwaliyo, kwaye ufakwe phantsi kobushushu obuphezulu kunye noxinzelelo oluphezulu kwisikhunta. Linamandla okusebenza kakuhle, amandla aphezulu oomatshini, iipropati ezilungileyo ze-dielectric, ukumelana okuhle kokulandelela kunye nokumelana ne-arc. Linesatifikethi se-UL kwaye liphumelele uvavanyo lwe-REACH kunye ne-RoHS, njl. Ikwabizwa ngokuba yi-GPO-3 okanye i-GPO3 sheet, i-GPO-3 okanye i-GPO3 insulation board.

Iyasebenza ekwenzeni izinto okanye iinxalenye zesakhiwo sokufaka ubushushu kunye nezokuxhasa kwi-F-class electric motors, ii-transformers, ii-switch gears, ii-circuit breakers kunye nezixhobo zombane. I-UPGM inokubunjwa ngokuthe ngqo ibe ziiprofayili ezahlukeneyo okanye iindawo zesakhiwo sokufaka ubushushu.

Uluhlu lokutyeba:2mm---60mm

Ubungakanani bephepha:1020mm *2010mm, 1000mm *2000mm, 1220mm *2440mm kunye nobunye ubukhulu okanye/kunye nobukhulu obuxoxiswana ngabo

Umbala ophambili: obomvu, omhlophe okanye eminye imibala exoxiswanayo

Ngaphandle kwamaphepha e-UPGM alaminethiweyo, sikwavelisa kwaye sinikezele ngamaphepha e-EPGM 203, ubukhulu bamaphepha bufana nobo be-GPO-3. Umbala utyheli okanye uluhlaza. Nceda unxibelelane nam ukuze ufumane ulwazi oluthe kratya.

Iimfuno zobugcisa

Inkangeleko

Umphezulu wayo mawube tyaba kwaye uthambile, ungabi namadyungudyungu, imibimbi okanye amaqhekeza kwaye ungabi nezinye iziphene ezincinci ezifana nemikrwelo, ukuqhekeka kunye nemibala engalinganiyo.

I-t eqhelekileyoukucaphuka kunyeukunyamezelana

| Ubukhulu obuqhelekileyo (mm) | Ukunyamezelana okuvunyelweyo (mm) | Ubukhulu obuqhelekileyo (mm) | Ukunyamezelana okuvunyelweyo (mm) | |

| 0.8 | +/-0.23 | 12 | +/-0.90 | |

| 1.0 | +/-0.23 | 14 | +/-1.00 | |

| 2.0 | +/-0.30 | 16 | +/-1.10 | |

| 3.0 | +/-0.35 | 20 | +/-1.30 | |

| 4.0 | +/-0.40 | 25 | +/-1.40 | |

| 5.0 | +/-0.55 | 30 | +/-1.45 | |

| 6.0 | +/-0.60 | 40 | +/-1.55 | |

| 8.0 | +/-0.70 | 50 | +/-1.75 | |

| 10.0 | +/-0.80 | 60 | +/-1.90 | |

| Qaphela: Kwiphepha lobukhulu obungengobuqhelekileyo elingadweliswanga kule theyibhile, ukuphambuka okuvunyelweyo kuya kufana nokobukhulu obukhulu obulandelayo. | ||||

Iipropati zomzimba, ezoomatshini nezombane

| Iipropati | Iyunithi | Ixabiso eliqhelekileyo | Ixabiso eliqhelekileyo | Indlela yovavanyo | ||

| Uxinano | g/cm3 | 1.65~1.95 | 1.8 | GB/T 1033.1-2008 | ||

| (indlela A) | ||||||

| Ukufunxwa kwamanzi, ubukhulu obuyi-3mm | % | ≤ 0.2 | 0.16 | I-ASTM D790-03 | ||

| Amandla okugobeka, ajonge ngqo kwii-laminations (Ubude) | Kwimeko eqhelekileyo | I-MPa | ≥180 | 235 | I-ASTM D790-03 | |

| 130℃+/-2℃ | ≥100 | 144 | ||||

| Imodulus eguquguqukayo, ethe nkqo kwii-laminations (Ubude) | Kwimeko eqhelekileyo | I-MPa | - | 1.43 x 104 | ||

| 130℃+/-2℃ | - | 1.10 x 104 | ||||

| Amandla okugobeka, ajonge ngqo kwii-laminations (Ubude) | Ubude obude | I-MPa | ≥170 | 243 | GB/T 1449-2005 | |

| Unqamlezo | ≥150 | 240 | ||||

| Amandla empembelelo, ahambelana ne-laminations | KJ/m2 | ≥40 | 83.1 | GB/T 1043.1-2008 | ||

| (UCharpy, akacholwanga) | ||||||

| Amandla empembelelo, ahambelana ne-laminations | I-J/m | - | 921 | I-ASTM D256-06 | ||

| (Izod, itshixiwe) | ||||||

| Tensile strength | I-MPa | ≥150 | 165 | GB/T 1040.2-2006 | ||

| Imodulus yokuqina kwe-tensile | I-MPa | ≥1.5x104 | 1.7 x 104 | |||

| Amandla okuxinana, ahambelana nee-laminations | Ubude obude | I-MPa | ≥55 | 165 | GB/T1447-2005 | |

| Unqamlezo | ≥55 | 168 | ||||

| Ithe nkqo kwii-laminations | I-MPa | - | 230 | I-ASTM D695-10 | ||

| Amandla oxinzelelo | ||||||

| Amandla e-dielectric, ajonge ngqo kwii-laminations (kwi-25# transformer oil kwi-90℃+/-2℃, uvavanyo lwexesha elifutshane, i-Φ25mm/Φ75mm cylindrical electrode) | I-KV/mm | ≥12 | 135 | IEC60243-1: 2013 | ||

| I-voltage yokwaphuka, ehambelana ne-animations (kwi-25# transformer oil kwi-90℃+/-2℃, uvavanyo lwexesha elifutshane, i-Φ130mm/Φ130mm plate electrode) | KV | ≥35 | >100 | |||

| Imvume ehambelanayo (1MHz) | - | ≤ 4.8 | 4.54 | GB/T 1409-2006 | ||

| Into yokusasaza i-dielectric (1MHz) | - | ≤ 0.03 | 1.49 x 10-2 | |||

| Ukumelana ne-Arc | s | ≥180 | 187 | GB/T 1411-2002 | ||

| Ukumelana nokulandelela | I-CTI | V | ≥600 | I-CTI 600 | ||

| I-overpass | GB/T 4207-2012 | |||||

| I-PTI | ≥600 | I-PTI 600 | ||||

| Ukumelana nobushushu | Kwimeko eqhelekileyo | Ω | ≥1.0x1013 | 5.4 x 1014 | GB/T 10064-2006 | |

| (Ii-electrodes ze-taper pin) | Emva kweeyure ezingama-24 emanzini | ≥1.0x1012 | 2.5 x 1014 | |||

| Ukutsha (Indlela ethe nkqo) | Ibanga | V-0 | V-0 | UL94-2013 | ||

| Ucingo olukhanyayo | - | - | I-GWIT: 960/3.0 | GB/T5169.13-2006 | ||

| Ubulukhuni beBarcol | - | ≥ 55 | 60 | I-ASTM D2583-07 | ||

Ukuhlolwa, Uphawu, Ukupakishwa kunye Nokugcinwa

1) Ibhetshi nganye kufuneka ivavanywe ngaphambi kokuba ithunyelwe. Izinto zokuhlola zoVavanyo oluQhelekileyo mazibandakanye iCandelo 2.1, 2.2, kunye neCandelo 1 kunye neCandelo 3 leTheyibhile 6 kwiCandelo 2.3. Izinto ezikwiCandelo 2.1, 2.2, mazitshekishwe nganye nganye.

2) La mashiti makagcinwe kwindawo apho ubushushu bungekho ngaphezulu kwama-40℃, aze abekwe ngokuthe tye kwipleyiti yombhede enobude obuyi-50mm okanye ngaphezulu. Gcina kude nomlilo, ubushushu (isixhobo sokufudumeza) kunye nelanga elithe ngqo. Ixesha lokugcina la mashiti ziinyanga ezili-18 ukususela kumhla wokuphuma kwifektri. Ukuba ixesha lokugcina lingaphezulu kweenyanga ezili-18, imveliso ingasetyenziswa emva kokuvavanywa ukuba ifanelekile.

Amagqabaza kunye namanyathelo okuphepha xa kusingathwa kwaye kusetyenziswe

1) Isantya esiphezulu kunye nobunzulu obuncinci bokusika kufuneka kusetyenziswe xa kusenziwa imashini ngenxa yokuguquguquka kobushushu obuphantsi kwamaphepha.

2) Ukuyisika le mveliso ngomatshini kuya kukhupha uthuli nomsi omninzi. Kufuneka kuthathwe amanyathelo afanelekileyo ukuqinisekisa ukuba amanqanaba othuli akwimida eyamkelekileyo ngexesha lokusebenza. Kucetyiswa ukuba kungeniswe umoya wokukhupha umoya kwindawo ethile kunye nokusetyenziswa kweemaski zothuli/zeenxalenye ezifanelekileyo.

Isiqinisekiso