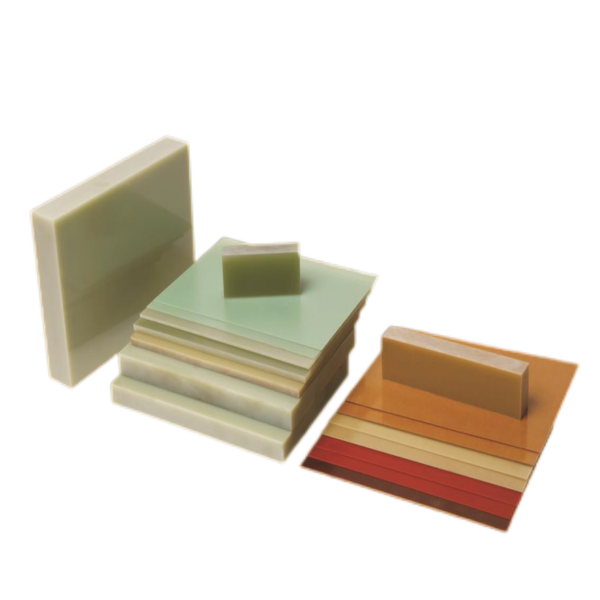

DF350A Modified Diphenyl Etere Glass Ilaphu Rigid Laminated sheet

DF350Aiqulathe ilaphu leglasi elukiweyo elifakwe idiphenyl ether thermosetting resin elungisiweyo, elaminethiweyo phantsi kobushushu obuphezulu kunye noxinzelelo. Ilaphu leglasi elilukiweyo aliyi kuba nealkali kwaye linyangwe nge-KH560.

I-DF350A inokumelana nobushushu okulungileyo, iipropathi ezigqwesileyo zoomatshini kunye ne-dielectric, zilungele ukusetyenziswa kwiimotor zombane zodidi lwe-H okanye izixhobo zombane njengeendawo zokugquma okanye izinto. Ngokukodwa ezisetyenziswa kwezi motors zombane okanye izixhobo zombane ezifuna ukusebenza ngoomatshini abaphezulu phantsi koxinzelelo lwe-thermal state.

Ubukhulu obukhoyo:0.5mm ~ 200mm

Ubungakanani bephepha elikhoyo:

1500mm * 3000mm, 1220mm * 3000mm, 1020mm * 2040mm, 1220mm * 2440mm, 1000mm * 2000mm kunye nezinye iisayizi thethwano.

Ukutyeba okuNgenisiweyo kunye noNyamezelo oluVunyiweyo (mm)

| Ubukhulu begama | Ukutenxa | Ubukhulu begama | Ukutenxa | Ubukhulu begama | Ukutenxa |

| 0.5 | +/-0.15 | 3 | +/-0.37 | 16 | +/-1.12 |

| 0.6 | +/-0.15 | 4 | +/-0.45 | 20 | +/-1.30 |

| 0.8 | +/-0.18 | 5 | +/-0.52 | 25 | +/-1.50 |

| 1 | +/-0.18 | 6 | +/-0.60 | 30 | +/-1.70 |

| 1.2 | +/-0.21 | 8 | +/-0.72 | 35 | +/-1.95 |

| 1.5 | +/-0.25 | 10 | +/-0.94 | 40 | +/-2.10 |

| 2 | +/-0.30 | 12 | +/-0.94 | 45 | +/-2.45 |

| 2.5 | +/-0.33 | 14 | +/-1.02 | 50 | +/-2.60 |

Ukugoba ukujikwa (mm)

| Ukutyeba | Ukugoba ukuphambuka | |

| 1000 (ubude bomlawuli) | 500 (ubude bomlawuli) | |

| 3.0 ~ 6.0 | ≤10 | ≤2.5 |

| 6.1-8.0 | ≤8 | ≤2.0 |

| >8.0 | ≤6 | ≤1.5 |

IiPropati zoMzimba, oomatshini kunye neDielectric

| Hayi. | Iipropati | Iyunithi | Ixabiso eliqhelekileyo | Ixabiso eliqhelekileyo | ||

| 1 | Ukuxinana | g/cm3 | 1.70-1.95 | 1.9 | ||

| 2 | Amandla e-Flexural, perpendicular to laminations (Ngobude) | Kwimeko eqhelekileyo | MPa | ≥400 | 540 | |

| 180℃+/-2℃ | ≥200 | 400 | ||||

| 3 | Amandla empembelelo (Charpy, notch, ubude) | kJ/m2 | ≥37 | 50 | ||

| 4 | Amandla okuncamathelisa/amandla ebhondi | N | ≥5000 | 6900 | ||

| 5 | Ukufunxwa kwamanzi | mg | Jonga itheyibhile elandelayo | 11.8 | ||

| 6 | Ukumelana ne-insulation, ihambelana ne-laminations | Kwimeko eqhelekileyo | MΩ | ≥1.0 x 106 | 5.3 x 107 | |

| Emva kwe-24h emanzini | ≥1.0 x 102 | 3.8 x 104 | ||||

| 7 | I-Dielectric dissipation factor 1MHz | -- | ≤0.05 | 1.03 x 10-2 | ||

| 8 | Dielectric rhoqo 1MHz | -- | ≤5.5 | 4.7 | ||

| 9 | I-voltage yokuqhekeka, ehambelana ne-laminations (kwi-oyile ye-transformer ku-90 ℃+/-2 ℃) | kV | ≥30 | 35 | ||

| 10 | Amandla eDielectric, perpendicular to laminations (kwioyile ye-transformer kwi-90 ℃ +/-2 ℃), ishidi le-2mm | MV/m | ≥11.8 | 18 | ||

Ukufunxwa kwamanzi

| Umndilili wobunzima beesampulu zovavanyo (mm) | Ukufunxwa kwamanzi (mg) | Umndilili wobunzima beesampulu zovavanyo (mm) | Ukufunxwa kwamanzi (mg) | Umndilili wobunzima beesampulu zovavanyo (mm) | Ukufunxa amanzi (mg) |

| 0.5 | ≤17 | 2.5 | ≤21 | 12 | ≤38 |

| 0.8 | ≤18 | 3.0 | ≤22 | 16 | ≤46 |

| 1.0 | ≤18 | 5.0 | ≤25 | 20 | ≤52 |

| 1.6 | ≤19 | 8.0 | ≤31 | 25 | ≤61 |

| 2.0 | ≤20 | 10 | ≤34 | Jonga amaNqaku-2 | ≤73 |

| Amagqabantshintshi:1) Ukuba umyinge obaliweyo wobunzima obulinganisiweyo uphakathi kobunzima obubini obukhankanywe kule theyibhile, amaxabiso aya kufunyanwa ngokuguqulwa. Ukuba umyinge obaliweyo wobunzima obulinganisiweyo ungaphantsi kwe-0.5mm, iivali aziyi kuba ngaphezu kwe-17mg. Ukuba umyinge obaliweyo wobunzima obulinganisiweyo ungaphezulu kwe-25mm, ixabiso aliyi kuba ngaphezulu kwe-61mg.2) Ukuba ubungqingqwa begama bungaphezulu kwe-25mm, buya kwenziwa ngomatshini ukuya kwi-22.5mm kwelinye icala. Icala lomatshini kufuneka libe mpuluswa. | |||||

Ukupakisha kunye noGcino

Amaphepha aya kugcinwa kwindawo apho amaqondo obushushu angekho ngaphezulu kwe-40℃, kwaye abekwe ngokuthe tye kwi-bedplate enobude obuyi-50mm okanye ngaphezulu.

Gcina kude nomlilo, ubushushu (izixhobo zokufudumeza) kunye nelanga elithe ngqo. Ubomi bokugcinwa kwamaphepha ziinyanga ezili-18 ukusuka kumhla wokushiya umzi-mveliso. Ukuba ixesha lokugcinwa lingaphezulu kweenyanga ezili-18, imveliso nayo ingasetyenziswa emva kokuba ivavanyiwe ukuba ifaneleke.

Amagqabantshintshi kunye noLumkelo lweSicelo

Isantya esiphezulu kunye nobunzulu obuncinci bokusika buya kusetyenziswa xa kusetyenzwa ngenxa yobuthathaka be-thermal conductivity yamaphepha.

Ukucoca kunye nokusika le mveliso kuya kukhulula uthuli oluninzi kunye nomsi. Amanyathelo afanelekileyo kufuneka athathwe ukuqinisekisa ukuba amanqanaba othuli angaphakathi kwimida eyamkelekileyo ngexesha lokusebenza. Ukukhupha umoya wendawo kunye nokusebenzisa uthuli olufanelekileyo / iimaski zamasuntswana ziyacetyiswa.

Amaphepha aphantsi komswakama emva komatshini, i-coating of insulating vanish iyacetyiswa.