Iphepha lokukhusela elibunjiweyo le-D370 SMC

Iphepha lokufaka i-insulation elibunjiweyo le-D370 SMC luhlobo lwephepha lokufaka i-insulation eliqinileyo le-thermosetting. Lenziwe nge-SMC kwi-mold phantsi kobushushu obuphezulu kunye noxinzelelo oluphezulu. Linesatifikethi se-UL kwaye liphumelele uvavanyo lwe-REACH kunye ne-RoHS, njl. Ikwabizwa ngokuba yi-SMC sheet, i-SMC insulation board, njl.

I-SMC luhlobo lwekhompawundi yokubumba amaphepha equlathe ifayibha yeglasi eqiniswe nge-resin ye-polyester engagcwaliyo, ezaliswe yi-fire retardant kunye nezinye izinto zokuzalisa.

Iishiti ze-SMC zinamandla aphezulu oomatshini, amandla e-dielectric, ukumelana okuhle komlilo, ukumelana nokulandelela, ukumelana ne-arc kunye ne-voltage ephezulu yokumelana, kunye nokufunxwa kwamanzi okuphantsi, ukunyamezelana okuzinzileyo kunye nokugoba okuncinci. Iishiti ze-SMC zisetyenziselwa ukwenza zonke iintlobo zeebhodi zokukhusela kwiigiya zokutshintsha ze-voltage ephezulu okanye ephantsi. Ingasetyenziselwa ukucubungula ezinye iindawo zesakhiwo se-insulation.

Ubukhulu: 2.0mm ~ 60mm

Ubungakanani bephepha: 580mm * 850mm, 1000mm * 2000mm, 1300mm * 2000mm, 1500mm * 2000mm okanye ezinye iisayizi ezixoxiswanayo

I-SMC

I-DMC

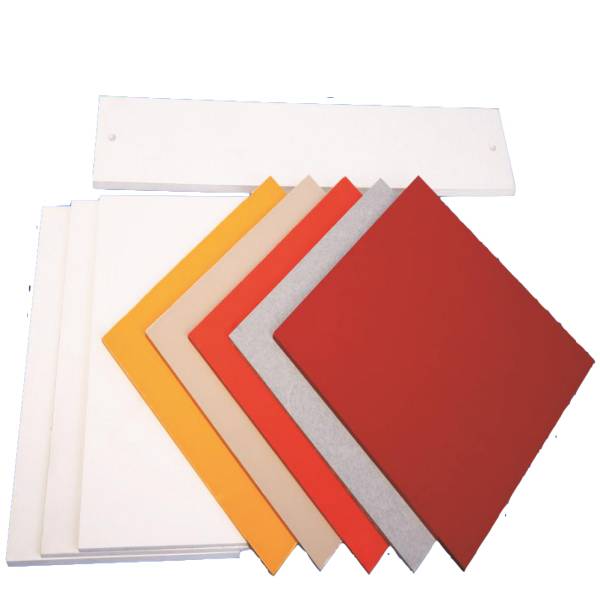

Amaphepha e-SMC anemibala eyahlukileyo

Amaphepha e-SMC

Iimfuno zobugcisa

Inkangeleko

Umphezulu wayo mawube tyaba kwaye uthambile, ungabi nazibhamuza, imifantu kunye nomonakalo obonakalayo woomatshini. Umbala womphezulu wayo kufuneka ufane, ungabi nafayibha ebonakalayo ecacileyo. Ungabi nangcoliseko ecacileyo, ukungcola kunye nemingxunya ebonakalayo. Ungabi naziphako kunye nokuqhekeka emaphethelweni ayo. Ukuba kukho iziphene kumphezulu wemveliso, zinokupeyintwa. Uthuthu oluninzi kakhulu kufuneka lucocwe.

I-bukuphela kokuphambukaIyunithi: mm

| Inkcazo | Ubungakanani bemilo | Ubukhulu obuqhelekileyo S | Ukugoba ukuphambuka | Ubukhulu obuqhelekileyo S | Ukugoba ukuphambuka | Ubukhulu obuqhelekileyo S | Ukugoba ukuphambuka |

| Iphepha le-D370 SMC | Ubude bamacala onke ≤500 | 3≤S<5 | ≤8 | 5≤S<10 | ≤5 | ≥10 | ≤4 |

| Ubude balo naliphi na icala | 3≤S<5 | ≤12 | 5≤S<10 | ≤8 | ≥10 | ≤6 | |

| 500 ukuya kwi-1000 | |||||||

| Ubude balo naliphi na icala ≥1000 | 3≤S<5 | ≤20 | 5≤S<10 | ≤15 | ≥10 | ≤10 |

Iimfuno zokusebenza

Iimpawu zomzimba, ezoomatshini nezombane zeeshiti ze-SMC

| Iipropati | Iyunithi | Ixabiso eliqhelekileyo | Ixabiso eliqhelekileyo | Indlela yovavanyo | ||

| Uxinano | g/cm3 | 1.65—1.95 | 1.79 | GB/T1033.1-2008 | ||

| Ubulukhuni beBarcol | - | ≥ 55 | 60 | I-ASTM D2583-07 | ||

| Ukufunxwa kwamanzi, ubukhulu obuyi-3mm | % | ≤0.2 | 0.13 | GB/T1034-2008 | ||

| Amandla okuguquguquka, angqamene ne-laminations | Ubude obude | I-MPa | ≥170

| 243 | GB/T1449-2005 | |

| Unqamlezo | ≥150 | 240 | ||||

| Amandla empembelelo, ahambelana ne-laminations (i-Charpy, engafakwanga i-notch) | KJ/m2 | ≥60 | 165 | GB/T1447-2005 | ||

| Tensile strength | I-MPa | ≥55 | 143 | GB/T1447-2005 | ||

| Imodulus yokuqina kwe-tensile | I-MPa | ≥9000 | 1.48 x 104 | |||

| Ukunciphisa ukubumba | % | - | 0.07 | I-ISO2577:2007 | ||

| Amandla oxinzelelo (athe nkqo kwii-laminations) | I-MPa | ≥ 150 | 195 | GB/T1448-2005 | ||

| Imodulus ecinezelayo | I-MPa | - | 8300 | |||

| Ubushushu bokuphambuka kobushushu phantsi komthwalo (T)ff1.8) | ℃ | ≥190 | >240 | GB/T1634.2-2004 | ||

| I-coefficient yokwandiswa kobushushu be-liner (20℃ -40℃) | 10-6/K | ≤18 | 16 | ISO11359-2-1999 | ||

| Amandla ombane (kwioyile yetransformer engama-25# kwi-23℃+/-2℃, uvavanyo lwexesha elifutshane, Φ25mm/Φ75mm, i-electrode ye-cylindrical) | I-KV/mm | ≥12 | 15.3 | GB/T1408.1-2006 | ||

| I-voltage yokuqhekeka (ihambelana ne-laminations, kwi-25# transformer oil kwi-23℃+/-2℃, uvavanyo lwenyathelo ngenyathelo lwe-20s, Φ130mm/Φ130mm, i-plate electrode) | KV | ≥25 | >100 | GB/T1408.1-2006 | ||

| Ukumelana nomthamo | Ω.m | ≥1.0 x 1012 | 3.9 x 1012 | GB/T1408.1-2006 | ||

| Ukumelana nomphezulu | Ω | ≥1.0 x 1012 | 2.6 x 1012 | |||

| Imvume ehambelanayo (1MHz) | - | ≤ 4.8 | 4.54 | GB/T1409-2006 | ||

| Into yokusasaza i-dielectric (1MHz) | - | ≤ 0.06 | 9.05 x 10-3 | |||

| Ukumelana ne-Arc | s | ≥180 | 181 | GB/T1411-2002 | ||

| Ukumelana nokulandelela | I-CTI

| V | ≥600 | 600 I-overpass | GB/T1411-2002

| |

| I-PTI | ≥600 | 600 | ||||

| Ukumelana nobushushu | Kwimeko eqhelekileyo | Ω | ≥1.0 x 1013 | 3.0 x 1014 | GB/T10064-2006 | |

| Emva kweeyure ezingama-24 emanzini | ≥1.0 x 1012 | 2.5 x 1013 | ||||

| Ukutsha | Ibanga | V-0 | V-0 | UL94-2010 | ||

| Isalathisi seoksijini | ℃ | ≥ 22 | 32.1 | GB/T2406.1 | ||

| Uvavanyo lwe-Glow-wire | ℃ | >850 | 960 | IEC61800-5-1 | ||

Melana nombane

| Ubukhulu obuqhelekileyo (mm) | 3 | 4 | 5~6 | >6 |

| Melana ne-voltage emoyeni kangangemizuzu eli-1 KV | ≥25 | ≥33 | ≥42 | >48 |

Ukuhlolwa, Uphawu, Ukupakishwa kunye Nokugcinwa

1. Ibhetshi nganye kufuneka ivavanywe ngaphambi kokuba ithunyelwe.

2. Ngokweemfuno zabathengi, indlela yokuvavanya i-voltage yokumelana nayo inokuxoxiswana ngayo ngokweeshiti okanye iimilo.

3. Ipakishwe ngebhokisi yekhadibhodi epalethini. Ubunzima bayo abudluli kwi-500kg ngepalethi nganye.

4. Amashiti kufuneka agcinwe kwindawo apho ubushushu bungekho ngaphezulu kwama-40℃, aze abekwe ngokuthe tye kwipleyiti yombhede enobude obuyi-50mm okanye ngaphezulu. Gcina kude nomlilo, ubushushu (isixhobo sokufudumeza) kunye nelanga elithe ngqo. Ixesha lokugcina amashiti ziinyanga ezili-18 ukususela kumhla wokuphuma kwifektri. Ukuba ixesha lokugcina lingaphezulu kweenyanga ezili-18, imveliso ingasetyenziswa emva kokuvavanywa ukuba ifanelekile.

5. Abanye baya kuthobela imiqathango ye-GB/T1305-1985,Imithetho ngokubanzi ye ukuhlolwa, iimpawu, ukupakisha, ukuthuthwa kunye nokugcinwa kwezinto zokushisa ezikhuselayo.

Isiqinisekiso