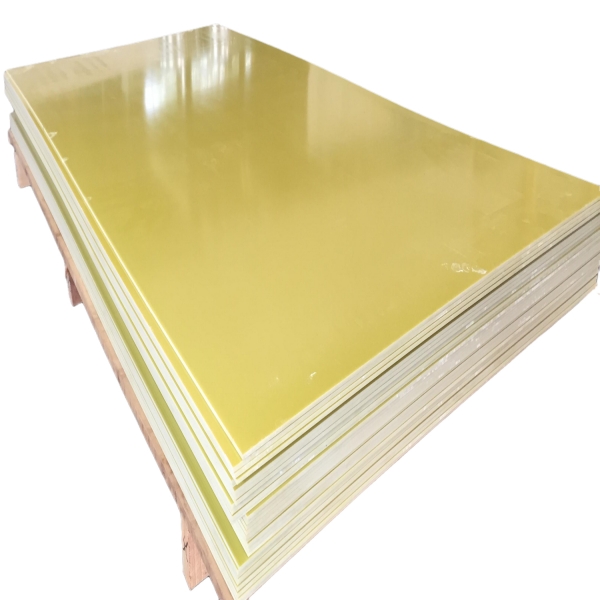

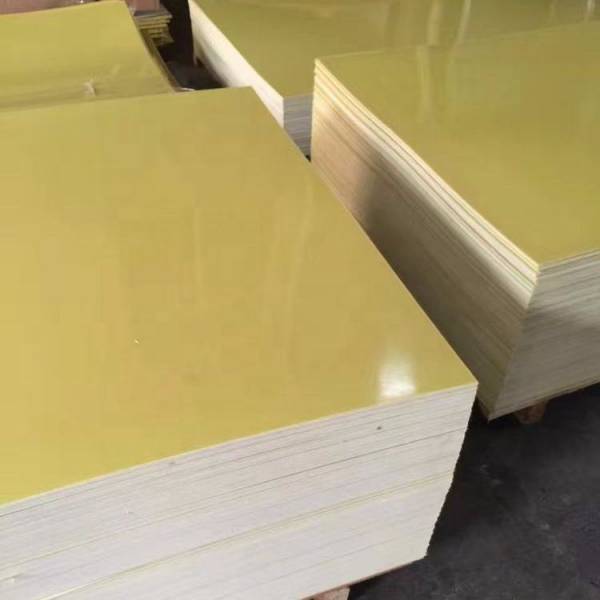

I-3240 Epoxy Phenolic Glass cloth Base Rigid Laminated Sheet

Iimfuno zobugcisa

1.1Inkangeleko:Umphezulu weshiti kufuneka ube tyaba kwaye ugudile, ungabi namaqamza omoya, imibimbi okanye amaqhekeza kwaye ungabi nezinye iziphene ezincinci ezifana nemikrwelo, ukuqhekeka, njl. Umphetho weshiti kufuneka ucoceke kwaye ungabi namaqhekeza kunye namaqhekeza. Umbala kufuneka ufane kakhulu, kodwa amabala ambalwa avumelekile.

1.2Ubungakanani kunye nokuvunyelwaukunyamezelana

1.2.1 Ububanzi kunye nobude bamaPhepha

| Ububanzi kunye nobude (mm) | Ukunyamezelana (mm) |

| >970~3000 | +/-25 |

1.2.2 Ubukhulu obuqhelekileyo kunye nokunyamezelana

| Ubukhulu obuqhelekileyo (mm) | Ukunyamezelana (mm) | Ubukhulu obuqhelekileyo (mm) | Ukunyamezelana (mm) |

| 0.5 0.6 0.8 1.0 1.2 1.6 2.0 2.5 3.0 4.0 5.0 6.0 8.0 | +/-0.12 +/-0.13 +/-0.16 +/-0.18 +/-0.20 +/-0.24 +/-0.28 +/-0.33 +/-0.37 +/-0.45 +/-0.52 +/-0.60 +/-0.72 | 10 12 14 16 20 25 30 35 40 45 50 60 80 | +/-0.82 +/-0.94 +/-1.02 +/-1.12 +/-1.30 +/-1.50 +/-1.70 +/-1.95 +/-2.10 +/-2.30 +/-2.45 +/-2.50 +/-2.80 |

| Amagqabaza: Kubukhulu obungengobuqhelekileyo obungadweliswanga kule theyibhile, ukuphambuka kuya kufana nobobukhulu obukhulu obulandelayo. | |||

1.3Ukuphambuka kokugoba

| Ubukhulu (mm) | Ukuphambuka kokugoba | |

| 1000mm (Ubude boMlawuli) (mm) | 500mm (ubude bomlawuli) (mm) | |

| 3.0~6.0 >6.0~8.0 >8.0 | ≤10 ≤8 ≤6 | ≤2.5 ≤2.0 ≤1.5 |

1.4Ukucubungula ngoomatshini:Amaphepha afanele angabi nazimfanta, aqhekeke kwaye angabi naziqwenga xa kusetyenziswa izinto ezifana nokusarha, ukubhola, ukugquma kunye nokugaya.

1.5Iimpawu ezibonakalayo, ezoomatshini nezombane

| Hayi. | Iipropati | Iyunithi | Ixabiso eliqhelekileyo | Ixabiso eliqhelekileyo |

| 1 | Uxinano | g/cm3 | 1.7~1.95 | 1.94 |

| 2 | Ukufunxwa kwamanzi (iphepha le-2mm) | mg | ≤20 | 5.7 |

| 3 | Amandla okugoba, angqamene ne-laminations | I-MPa | ≥340 | 417 |

| 4 | Amandla empembelelo (iCharpy, inotshi) | kJ/m2 | ≥30 | 50 |

| 5 | Into yokusasaza i-dielectric 50Hz | --- | ≤5.5 | 4.48 |

| 6 | I-dielectric constant 50Hz | --- | ≤0.04 | 0.02 |

| 7 | Ukumelana nobushushu (Emva kweeyure ezingama-24 emanzini) | Ω | ≥5.0 x108 | 4.9 x109 |

| 8 | Amandla e-dielectric, ajonge ngqo kwi-laminations kwi-oyile ye-transformer kwi-90℃+/-2℃, iphepha le-1mm | kV/mm | ≥14.2 | 16.8 |

| 9 | I-Breakdown Voltage, ehambelana ne-laminations kwi-transformer oil kwi-90℃+/-2℃ | kV | ≥35 | 38 |

Ukupakisha, Ukuthuthwa kunye nokugcinwa

La mashiti makagcinwe kwindawo apho ubushushu bungekho ngaphezulu kwama-40℃, aze abekwe ngokuthe tye kwipleyiti yombhede enobude obuyi-50mm nangaphezulu. Gcina kude nomlilo, ubushushu (isixhobo sokufudumeza) kunye nelanga elithe ngqo. Ixesha lokugcina la mashiti ziinyanga ezili-18 ukususela kumhla wokuphuma kwifektri. Ukuba ixesha lokugcina lingaphezulu kweenyanga ezili-18, imveliso ingasetyenziswa emva kokuvavanywa ukuba ifanelekile na.

Amagqabaza kunye namanyathelo okhuseleko xa ufaka isicelo

Isantya esiphezulu kunye nobunzulu obuncinci bokusika kufuneka kusetyenziswe xa kusenziwa imashini ngenxa yokuguquguquka kobushushu obuphantsi kwamaphepha.

Ukuyisika le mveliso ngomatshini kuya kukhupha uthuli nomsi omninzi. Kufuneka kuthathwe amanyathelo afanelekileyo ukuqinisekisa ukuba amanqanaba othuli akwimida eyamkelekileyo ngexesha lokusebenza. Kucetyiswa ukuba kubekho umoya ophumayo kwindawo ethile kunye nokusebenzisa iimaski zothuli/zeenxalenye.

Amashiti afunxwa kukufuma emva kokuba enziwe ngomatshini, kucetyiswa ukuba agqunywe nge-insulating vanish.

Izixhobo zeMveliso

Iphakheji yeeSheets eziLaminated